A tube ice machine is a refrigeration system that produces tube-shaped ice. It’s a great option for restaurants, bars, and other businesses that require large quantities of high-quality ice. The machine works through a simple refrigeration process, and it can produce up to 100 tons of ice per day. This makes it an ideal choice for large food and beverage companies that need to chill products quickly. This article will discuss how a tube ice machine works, how it can benefit your business, and what features to look for when choosing the right machine for your needs.

The ice making process begins when the ice machine’s water tank is filled with clean, fresh water. A water pump then transports the water to a filter, where it is cleaned and filtered to remove any impurities that might affect ice quality or safety. Once the water is clean, it’s transported back to the ice machine to begin the cooling process.

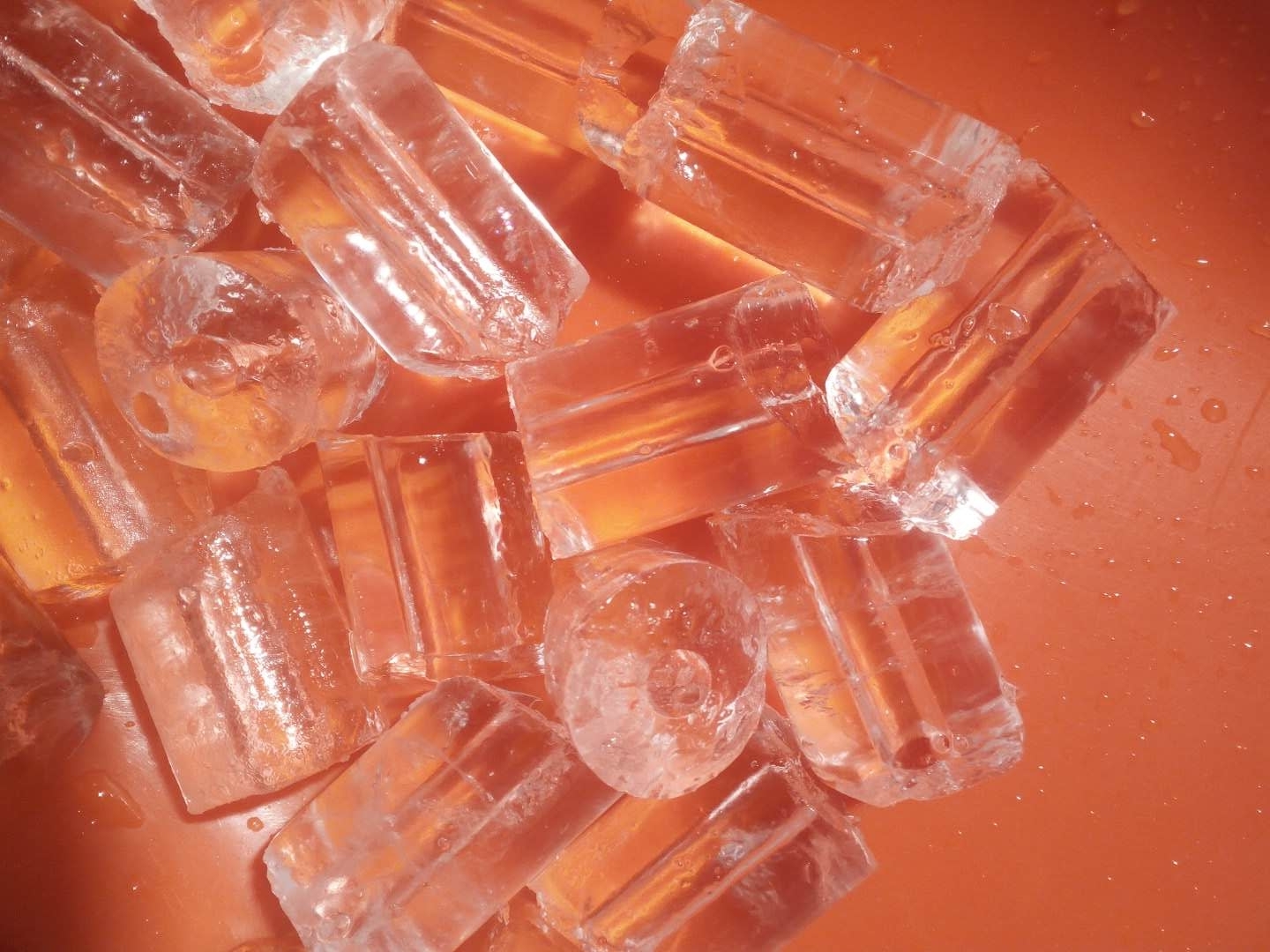

During the cooling process, refrigerant is circulated over a cold plate, which has an array of cylindrical holes. The refrigerant cools the holes, causing them to freeze and form tube-shaped ice. Once the ice is frozen, it’s transferred to a storage bin for future use.

Advantages of Tube Ice Machine

Compared to other types of industrial ice machines, tube ice machines are extremely reliable and efficient. They have fewer components, so they’re less likely to break down and require maintenance. They also have a smaller footprint, which allows them to fit into tight spaces and reduces installation costs. Lastly, tube ice machines are more energy-efficient than other types of ice makers, so they save money in the long run.

Another advantage of a tube ice machine is that it produces higher-density ice than other types of ice. This means that it can be used for longer periods of time and will last longer than other types of ice. It also has a more uniform appearance and texture than other types of ice, which is attractive to customers.

Vogt Industrial Ice Makers

A Vogt tube ice machine is the most efficient ice unit available, using only two pipes and one accumulator for an entire production cycle. Its design and construction make it a true integrated freezer. The patented heat exchanger and accumulator are combined into one unit, which eliminates the energy loss caused by having two separate pipes. This results in a significant reduction in operating temperatures and a much more stable operating temperature. The resulting ice is of exceptional quality with minimal chips and fines. This produces a more sized product and increases the amount of usable ice per bag. As a result, there’s less waste and more profit for your company. In addition, Vogt’s superior design eliminates the need for expensive ice screening and sizing equipment, saving you even more money.