Slurry ice machine is used in applications where large quantities of ice are needed to cool and preserve product, such as packing produce cases. This ice is not only more efficient than traditional solid ice, but it can also be delivered in much larger quantities with significantly lower energy consumption and labor costs. In addition, slurry ice is more hygienic than solid ice, and it can be easily pumped to where it’s needed.

The slurry ice machines can be sized to meet any cooling application. They can be used for industrial, medical and food packaging applications. They are also useful for delivering high-quality water for drinking or for use in cleaning and sanitation. They are made from stainless steel and can be used in a wide range of temperatures and conditions. The ice can be mixed with water, or it can be added to a refrigerated storage tank to cool products before they are transported.

Argonne National Laboratory is developing a system to deliver slurry ice to multiple locations throughout the campus. A central ice plant is used to make slurry ice, which is then transported through pipes to each of the buildings with the cooling load. This technology allows the ice to be distributed much more efficiently than before, and it can be supplied to large sites with a relatively small amount of equipment.

It is possible to reduce energy consumption by a factor of up to 15 when using slurry ice compared to traditional ice, which means a significant reduction in operating costs for these systems. In many cases, the capital costs of the slurry ice system are lower as well. This is a result of the fact that slurry ice does not require a cooling tower or similar system, and it requires much less maintenance than solid ice.

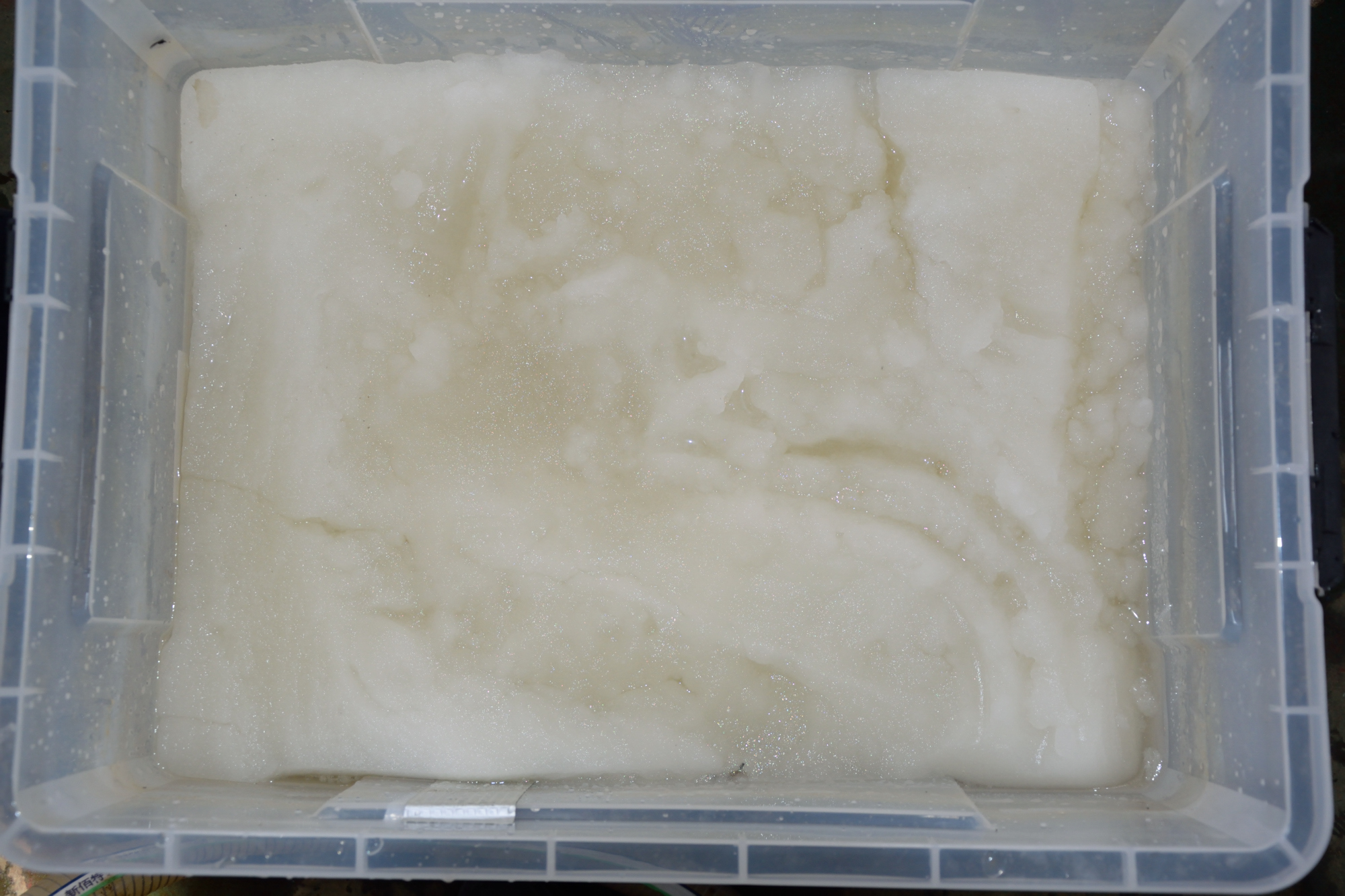

Slurry ice can be used to chill food products during storage and transport, and it is especially suitable for delicate foods such as fruits and vegetables. The ice crystals are very smooth, which prevents product damage and skin discoloration. This is in contrast to other forms of ice, such as flake or shell ice, which can cause freezer burn on product.

Slurry ice can be pumped anywhere, and it has many applications, including fish cooling on a fishing vessel. It has low energy costs and is easy to install. Its compact design and small occupied area make it an ideal choice for space-limited applications. It is also operated with a low brine concentration, which saves energy and reduces operating costs. It is available in a variety of capacities, from 3 ton up to 80 ton. The parts in contact with the brine solution are made from 316 stainless steel, and it is designed to comply with all food processing standards. Moreover, it uses less Freon than other solid ice types. This slurry ice machine is the most economical model on the market. It is also safe to use, and it has a long service life.